Flexible connectors were originally designed to reduce the amount of noise and vibration emitted by the exhaust system in a vehicle. Most commonly flexible connectors are positioned between the exhaust manifold and the front pipe in cars with transverse engine and front-wheel drive.

"Gradually, the use of flexible connectors has also spread to other parts of the exhaust system and in connection with turbochargers", says Christian Lund Andersen, Product Manager for flexible connectors at Triscan and continues: "It is precisely the diverse use that determines which of the three types/constructions of flexible connectors to be used. In principle you distinguish between the maximum temperature to which the flexible connector is exposed, but also whether there are special requirements for the flexible connector's ability to handle vibrations”.

Up to 650° C

For petrol engines, flexible connectors with a working range up to 650° C are used at the rear muffler. For diesel engines, this type of flex pipe connector is used immediately after the particulate filter.

Up to 800° C

Flexible connectors that can withstand temperatures up to 800° C are typically located at the start of the exhaust system. Besides being the place with the highest temperature, this part of the exhaust system is also where the pressure is the highest. The flexible connector must therefore designed in a three-layer construction, where the inner layer is of the interlock type.

The same applies in cases where the flexible connector is used in connection with the turbo system's wastegate/relief valve - for example in the VW Touran - with the aim of reducing the amount of vibrations transmitted to the turbocharger.

Special requirements for vibration damping

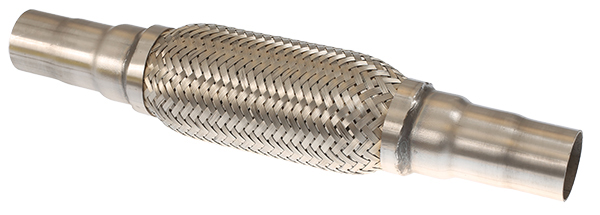

In applications with particularly high requirements for vibration damping, the flex pipe connector's ability to absorb vibrations - for example diesel engines or 3-cylinder petrol engines - it is recommended to use flexible connectors of the softflex type as shown here. Although the outer layer of the flex pipe connector is braided in an open construction - and compared to the denser type of braid at first seems less strong - the opposite is actually the case. The braiding method and the wire used actually give the flexible connector greater strength at the same time as better properties in relation to vibration damping.

Flex pipe connector of the softflex type is particularly suitable for vibration damping

Triscans programme of flexible connectors and connectors with clamps

Triscan's programme of flex pipe connectors includes 57 references. 47 is made in a three-layer construction, which can be used at temperatures below 650° C. The remaining 10 references can be used at temperatures up to 800° C. 8 of the 10 references are of the softflex type and the remaining 2 are uniflex pipes, which can be adapted to be used for three different pipe diameters. The flex pipe connectors are made of a particularly good quality in stainless steel - SS 304 - and are available depending on the type with short or long branches. "Flex pipe connectors live a vulnerable life and we have therefore chosen to manufacture our programme in extra good and durable materials", concludes Christian Lund Andersen. In addition to flex pipe connectors, Triscan also offers a programme of a total of 18 different connectors with clamps.

Uniflex pipe connectors are made in a three-layer construction, where the inner layer is of the interlock type

See our programme here...