How do we ensure a uniformly high quality and very low complaint rate on TRISCAN products? And how do we ensure that production takes place under orderly conditions? We tend to say ourselves: We do this by doing things a little different. In this article you can read more about some of the special conditions in which Triscan stands out.

We pay all our manufacturers a visit

The production of spare parts takes place world wide - and especially outside Europe, there can be a big difference in the conditions under which production takes place. Although it is both expensive and time consuming, our product managers always visit a new manufacturer prior to establishing a collaboration. One of the advantages of such visits is that we get clarified whether the production conditions live up to our strict requirements.

Certifications and onsite audits

Triscan spare parts are often manufactured by subcontractors to the automotive industry who are certified according to the industry's strict quality assurance standard - IATF 16949. If a manufacturer is not certified according to IATF 16949, we are satisfied with a certification according to ISO 9001 in cases where the parts being produced do not pose any safety risk.

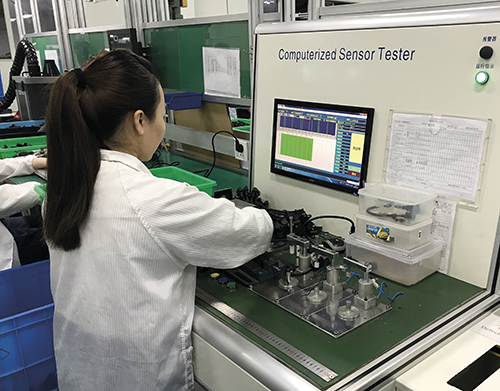

In addition, we conduct occasional audits with our manufacturers in Asia using our own local engineers.

Tests, spot checking and sample stock

Although we ensure that Triscan spare parts are subject to rigorous quality control during manufacture by our manufacturers, we do not stop here. When receiving goods, we carry out random checks of various kinds. It can for example be:

- 100% control for first-time deliveries - also accessories

- Checking dimensions according to technical drawings

- Product comparison according to our comprehensive sample stock

- Functional or material testing in our in-house test center

- Tests conducted by independent external institutes

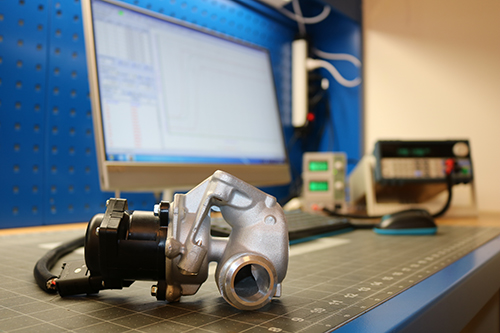

In-house testcenter

There are several reasons why it is important for us to have our own in-house testcenter. It gives us i.a. posibilities for:

- Conduct our own testing of new products from potential new manufacturers

- To conduct comparative tests

- To significantly reduce processing time on complaints

You can watch a video from our testcenter - and find examples and descriptions of some of the equipment that we have at our testcenter here...

Although we make sure that our spare parts are subject to strict quality control during the manufacture at our manufacturers, we carry out random checks in our in-house testcenter

Does it work then?

Our smart sourcing process has come into existence during many years and is based on our more than 40 years of experience. At the same time, we of course continuously monitor the development in our complaint statistics - not only overall, but also at product group and item number level. Over the past 12 months, we have once again managed to reduce the average complaint rate to a historically low level of 0.21%. Said in all modesty: It seems not so bad at all!