In an earlier article, we pointed out how difficult it can be to find the root cause of a lambda sensor error message. That article mainly addressed the broadband type. However, troubleshooting for the causes of error codes for conventional lambda sensors can be a long process as well - and often the problem is not the lambda sensor.

Although the lambda sensor is a wear part - and the mileage determines its lifespan, one should be able to expect it to last at least the warranty period (three years in Triscan’s case). However, the Lambda sensor is part of a complex system whose functionality is affected by many factors that can lead to errors.

Noteworthy in this context, are the very popular universal lambda sensors, in which the original plug is reused. Here, the cable must be soldered, insulated and finally encapsulated, so that the entire compound can withstand heat, cold, moisture, salt and dirt. This method is slow, carries a high risk of connecting the sensor incorrectly and is very vulnerable at the soldered connection. For this reason, Triscan’s program includes only "plug & play" lambda sensors, which exclude this source of error and ensures trouble-free and long-lasting repairs. Unsurprisingly, the fist suspicion for the cause of a lambda sensor error code is a defective lambda sensor.

Experience shows, however, that the error is very often found elsewhere. Below, we offer advice and guidance on how to effectively troubleshoot the problem.

During the production of Triscan lambda sensors, each sensor is subjected to a 100% functionality test

If the replacement of the lambda sensor does not eliminate the problem

If installing a new sensor does not solve the problem immediately - and the error codes are still logged - you should firstly ensure that the correct lambda sensor has been installed. It is not uncommon to have to choose between several variants for a particular car model. Despite having the same connector, thread, and cable length, they are often different.

Since Triscan lambda sensors are 100% functionality-tested during production, given you have selected the correct lambda sensor, you can assume the sensor is not the problem. Instead, troubleshooting should focus on:

• Sooty spark plugs. Note: Sooted/damaged spark plugs can damage the ignition coil

• Blown fuse of lambda sensor heating element (relevant only for broadband-types)

• Fuel trim that has not been reset after replacing the sensor (for relevant vehicles)

• Pollution by oil, silicone, leaded fuel, additives, etc. can damage the new sensor (the photos in the next section point out what to look for)

• Leaks in general. For example, in the following parts: intake manifold, vacuum hose, turbo hose, EGR valve and so on

• The injection system - including pump, fuel filter, pressure regulator or injectors. Check the fuel pressure, the fuel filter, the pressure regulator for leaks and injectors for contamination

• Other defective sensors - as a trigger of the error codes. For example, air flow meter, cooling water temperature sensor, EGR valve, crankshaft or camshaft position sensors

In older Lambda sensors the cause can also be found here:

Before replacing an older lambda sensor, it is advisable to take a closer look at the sensor, to find any signs of error causes other than normal wear and tear. If this is the case, there are usually clear indications to be found on the lambda sensor itself, the wire or the connector.

|

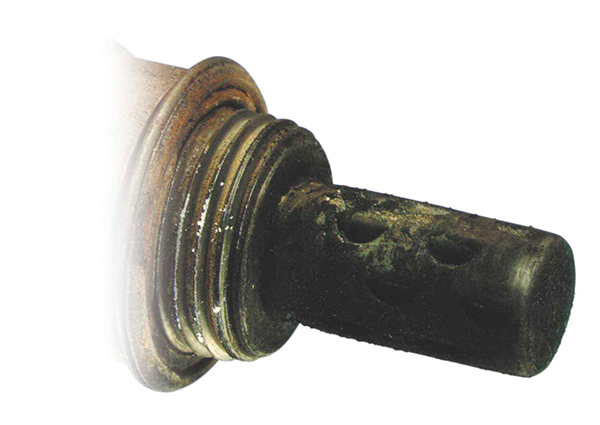

POLLUTION FROM OIL |

|

|

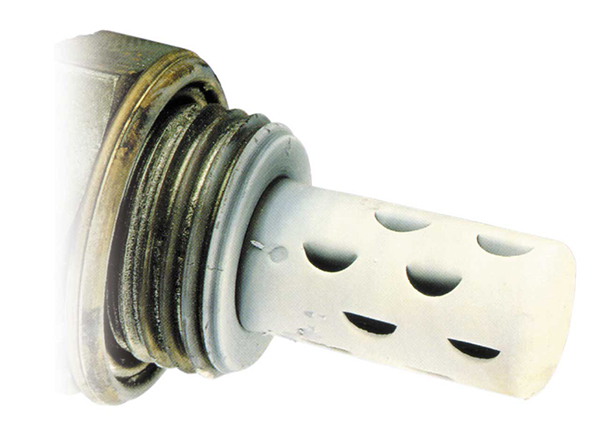

POLLUTION FROM SILICONE |

|

|

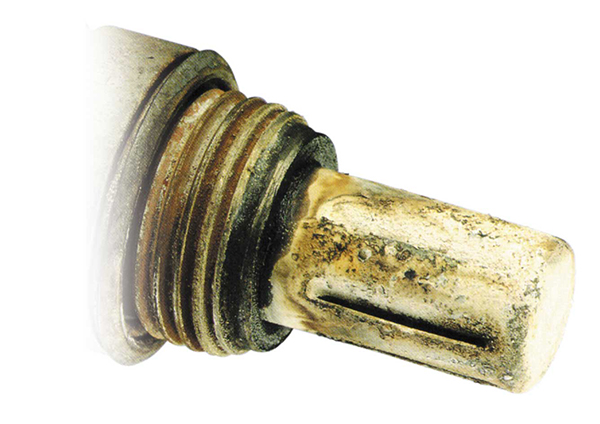

POLLUTION FROM COOLANT |

|

|

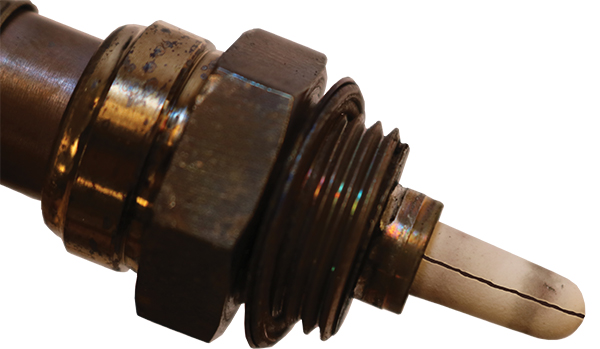

CRACKED LAMBDA ELEMENT (protective cap removed for examination) |

|

|

|

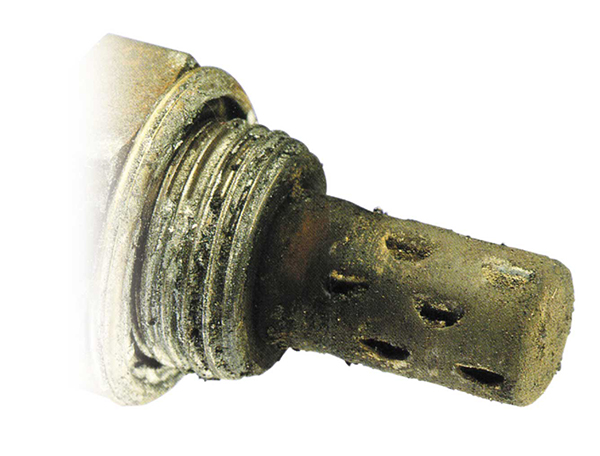

POLLUTION FROM A RICH FUEL MIXTURE |

|

|

|

THE RESULT OF A STONE CHIP |

|

|

THE RESULT OF HEAT INFLUENCE |

|

|

|

THE RESULT OF A CABLE BREAK/THE RESULT OF TWISTING THE CABLE |

|

|

POLLUTION FROM FUEL ADDITIVE | |

|

POLLUTION FROM LEAD |

|

|

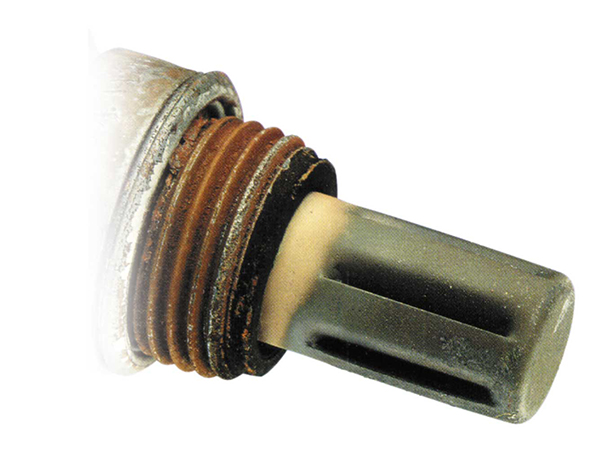

USE OF THE WRONG LAMBDA SENSOR |

A simple error message with a variety of possible error sources

As this article illustrates, discussing the actual error source for a lambda sensors error message can be quite difficult and time consuming. Without the necessary insight, test equipment and patience, the first impulse - replacing the lambda sensor - does not necessarily solve the problem. We hope this article will help mechanics in these situations - and contribute to greater customer satisfaction.

|

|