The development of new technological breakthroughs in the automotive industry has increased exponentially and the speed with which they are implemented in the vehicles has increased. Since its introduction, the brake system's ABS sensor has become an important source of information for a large number of the vehicle's other systems. ESP, adaptive cruise control, parking assistant, iTPMS to name a few. However, since the type of information that the various systems need differs from what the ABS sensor was originally created for, it has been necessary to develop new technology, which on several occasions has proven to cause problems for many workshops.

The challenges most often relate to ABS sensors with AMR (Anisotropic Magneto-Resistive) technology, which is the successor to the otherwise most commonly used Hall effect type. Contrary to the type of chip used in a Hall effect sensor, the chip for AMR type sensors is produced primarily by the company NXP in Malaysia.

Both types of sensors are in several cases to be found in the same models of vehicles where to the eye they do not differ. They can both be installed without any problems and have the same plug connection. In the effort to keep production costs down, the manufacturers have thus ultimately created a potential problem for the workshops. Asger Thybo Geertsen, CPO at Triscan a/s tells,

” Unfortunately, we have received many complaints about ABS sensors that relate to the use of the wrong type of ABS sensor. If you use a supplier who does not have both variants available, are not aware that there are two variants or order in good faith based on an incorrect cross number - then we have trouble”.

A very common example of the above is certain model types of the Mercedes Sprinter and Volkswagen Crafter vans. Models supplied with parking assistant or adaptive cruise control use the AMR type, otherwise the Hall type must be used.

Unfortunately, the challenges for the workshops do not stop here. The latest development within AMR technology has meant the development of a new type of chip, which can also give workshops a headache.

” The latest generation of AMR chips has been improved in several areas and is especially used in vehicles with an indirect tire pressure monitoring system - iTPMS. We also exclusively use AMR chips produced by NXP”.

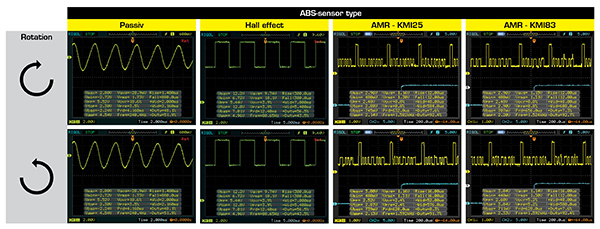

Like the aforementioned example, it is not possible for the eye to see any difference between whether the sensor is a generation 1 or 2. The first generation of chips carries the technical designation KMI25 and the second generation KMI83. However, there are three factors in particular that are important to keep in mind.

- Vehicles with adaptive cruise control, parking assistant or iTPMS use AMR technology.

- Only second-generation AMR chips are backwards compatible.

- Some testers misdiagnose AMR-type ABS sensors even though the vehicle is working fine and not self-diagnosing.

When people in Triscan's product department become aware of conditions that are out of the ordinary and therefore cause problems for the workshops, smartrep.info is used. Spare parts that require special attention during selection and assembly are provided with a clear label on the packaging. In addition to a warning triangle, the label is also printed with a website address - www.smartrep.info - and a QR code which, when scanned, goes directly to the website. On the home page of the website, enter the item number from the product's barcode label, followed by information about special conditions, assembly and any required use of special tools is explained.