Recently, our fastest growing product family got a new member - and our sensor programme now includes a total of 12 sensor types. In this article you will learn more about our parking sensors: What does the programme include? Where are they used? Which systems are there? How do they work? What should you pay attention to? How do we test it?

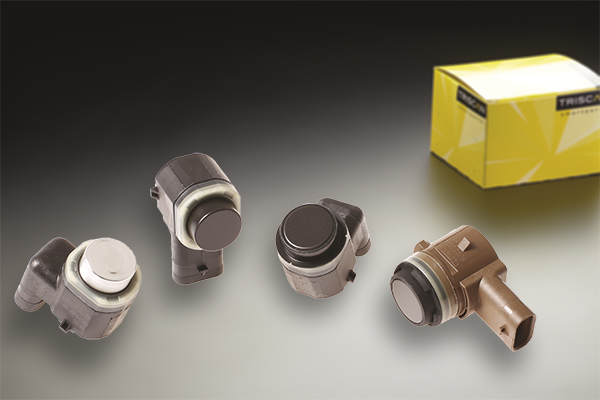

Our new parking sensor programme includes more than 70 OE-quality references. The electronic components used are sourced from leading OEM manufacturers and each sensor undergoes a performance test as part of the manufacturing and quality assurance process. Most Triscan parking sensors are made of black plastic. The sensors can be painted but must be painted with a plastic primer before.

Where they are used

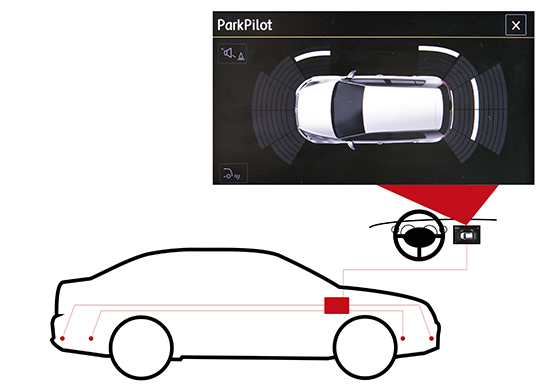

Parking sensors are used in systems that assist the driver when parking or maneuvering a vehicle by detecting and indicating the distance to obstacles to avoid accidents. The systems indicate the distance of the vehicle to an obstacle either visually, by sound or a combination of both.

3 systems with different technologies

- Ultrasound system

- Electromagnetic system

- Camera-based system

The most widely used system uses ultrasonic sensors and is easily recognized by the visible sensors in the vehicle bumpers. Triscan's vehicle-specific sensors programme includes only sensors for ultrasound systems.

How does an ultrasound sensor work?

An ultrasonic sensor is capable of transmitting and detecting high-frequency sound waves. These sensors can thus convert electrical voltage into sound waves and audio waves into electrical voltage. The sensor uses a piezoelectric transducer whose crystals change in size and shape when applied to electrical power, producing sound waves. However, the crystals can also generate electrical voltage when subjected to pressure, which also allows them to detect sound waves. The sensor can transmit and record ultrasound in the range of 60-800 kHz. By generating an analog output, the sensor can measure the distance of a given object.

Great differences in quality

Two of the most important components of an ultrasonic sensor - and one of the most common causes of sensor malfunction - are the sensor and the microchip. Unfortunately, there are too many manufacturers using components of questionable quality - causing malfunction. A Triscan parking sensor incorporates components from leading OEM suppliers, and each sensor was tested for impeccable functionality before leaving the factory.

In-house test equipment

To offer and ensure a high level of service and quality, we continuously invest in our own test equipment. We have also done that in terms of parking sensors. Our parking sensor tester is used in the selection of manufacturers, the development of new products, spot checks and the handling of complaints. Thus, among other things, we can coordinate the quality of our products with original products. Furthermore, it helps giving our customers timely and precise feedback in case of warranty claims.

Many advantages

In other words, there are several good reasons to take a closer look at our new product group. A broad coverage, good quality and competent customer service, coupled with high delivery capability has been known to satisfy customers.