All too often it is not the oxygen sensor, which is responsible for the error messages, that generally point in that direction. This especially applies in the case where wideband sensors are used instead of conventional O2 sensors. This is also why, it is very important to pay extra attention in the troubleshooting process with this kind of sensor. Learn more about the system design and source of errors in this article.

Frank Donslund, owner and director of Elektro Partner, providing hotline and technical solutions for car workshops in Denmark, Norway and Sweden (Autodata, TEXA, Delphi and Nextech) states: "In our hotline, we daily experience answering questions related to oxygen sensors. To many oxygen sensors are replaced solely on the basis of error codes and for no reason. It is especially the very delicate wideband type that often causes problems for the workshops".

Purpose, function and difference

The purpose of the oxygen sensor is to ensure, that the engine control unit (ECU) ensures the correct mixture of fuel and oxygen in any given situation. This is done by performing a continuous measurement of the exhaust gas composition. A conventional O2 sensor is only able to measure the amount of oxygen (O2) in the exhaust gas and switch between two signals - one for rich and one for lean mixture. A wideband sensor is on the other hand, able to provide a much more detailed and varied image of the composition of oxygen and fuel within a broader range.

Both types of sensor-measurements are based on measurement of changes in voltage. However, for the mechanic it is important to know that the difference between wideband sensors and conventional O2 sensors is, that the voltage rises (does not go down) when the fuel mixture becomes lean. Another difference is that the voltage signal comes from the vehicles ECU and not from the sensor itself. Therefore, you cannot read the output voltage of a wideband sensor directly with a digital oscilloscope (DSO), like you do with conventional O2 sensors.

Another thing that the mechanic also should be aware of is, that the value read for a wideband sensor on a tester can be misleading. Many testers with "generic" OBD II software automatically convert the motor control's wideband sensor voltage output to a 0 to 1 volt scale, just like a conventional O2 sensor. This leads to that voltage does not change as much as you would expect when you running in lean or rich mixture, and you may wrongly conclude that the wideband sensor is malfunctioning. The most accurate way to test a wideband sensor is with a factory tester that shows the actual voltage reading of the engine control - or an aftermarket tester that is capable of doing so.

If you want to know more about sources of errors and troubleshooting, you can read more here...

Contamination

A soiled sensor cannot convey an accurate reading of the air/fuel mixture. In this sense, wideband sensors and O2 sensors are equally sensitive. There are many sources of contamination:

- Cooling water from leaks in the cooling system (leaky cylinder head gasket or cracks in the cylinder head)

- Phosphorus from engine oil that has found its way to the combustion chambers (worn valve guides and seals, worn piston rings or cylinders)

- RTV sealers with a high content of silicone

- Certain petrol additives

A lightly soiled oxygen sensor reacts slowly to sudden changes in the air/fuel mixture. If the oxygen sensor is highly soiled, it does not react at all.

Leaks and malfunction

Besides contamination, compression leaks or malfunctions can confuse the oxygen sensor, which leads to incomplete combustion causing high levels of oxygen in the exhaust system. This is also the case with a leaking exhaust manifold.

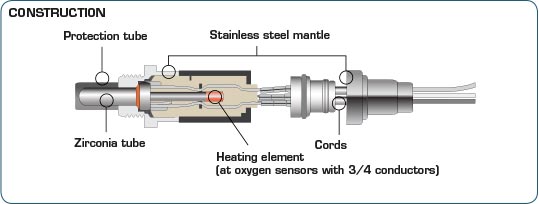

Wideband sensor heater circuit

Another source of oxygen sensor error codes can be the heater of the wideband. A wideband sensor requires a higher operating temperature (650° C) than a conventional O2 sensor (350-400° C). If the heater or the wiring circuitry does not work optimally, the sensor cannot achieve the correct operating temperature.

A too low temperature will normally - but not always - cause an error code. In any case, ALWAYS check the wiring circuitry for malfunctions - including supply voltage and ground - before deciding whether the sensor itself is malfunctioning.

On V6 and V8 engines, where two wideband sensors are used (one for each cylinder row), the heaters are usually controlled by a relay. The power consumption of the heater circuit is controlled by the ECU. In case of a cold engine, the power consumption is high to ensure that the wideband sensors achieve operating temperature as quick as possible. The ECU monitors the performance of the heaters and sets an error code if an error occurs. At the same time, the power to the heaters is switched off.

What other possible sources of error are there?

A engine running on a rich or lean mixture often triggers a P0172 or P0175 at a rich mixture and a P0171 or P0174 at a lean mixture. But where do you start your troubleshooting? You can assume that there is a malfunctioning wideband sensor, but there are many other possible sources of error. Lean codes are triggered when the measured LTFT - Long Term Fuel Trim (mixture measured over a long time) is too lean. Connect a tester and check if the engine has a lean mixture condition by looking at the LTFT value. The normal range is typically between +5 to -5. If the reading is 8 to 10 or higher, the ECU needs to add additional fuel to compensate for a reading indicating a lean mixture. The same goes for a rich mixture, but here the LTFT number is in minus.

Vacuum leakage or EGR valve

This may be due to a vacuum leakage in the intake manifold, a loose vacuum hose or an EGR valve that does not close.

Fuel pump, fuel filter, pressure regulator or injection nozzles

If none of the aforementioned sources of error can be identified, the fuel supply should be checked. A too low fuel pressure - for example due to a worn fuel pump, a blocked fuel filter or a leaky fuel pressure regulator - may also be the cause of a lean mixture. Soiled injection nozzles are another possible source of error.

Airflow meter

If the fuel system does not show any signs of error, the calculated load value should be checked using a tester. Watch out for changes in the specified airflow as you speed up the engine. If the sensor in the airflow meter is soiled, it may cause a too low value for the airflow to be passed to the ECU (which leads to a lean mixture).

Cooling water temperature sensor

If the airflow meter appears to work properly, check the function of the cooling temperature sensor for proper reading. By cold engine, the cooling water temperature reading is compared with the temperature reading from the intake air of your tester. Both measurements should be identical. A difference of more than a few degrees indicates a problem.

Soiled or malfunctioning wideband sensor

If everything is all right, the problem may be a soiled or malfunctioning wideband sensor(s) that does not measure accurately. On Toyotas, a factory tester can perform an "Active Test A/F Controls". The function is located under the menu Diagnosis, Enhanced OBD II, Active Test, A/F Control. The test changes the mixture - while the engine is idling - in order to test the response of the wideband sensor.

Typical OBD II error codes for wideband sensors

Generic OBD II codes, that indicates an error in the wideband sensors heater, include: P0036, P0037, P0038, P0042, P0043, P0044, P0050, P0051, P0052, P0056, P0057, P0058, P0062, P0063 and P0064. Codes that indicate a possible error in the actual wideband sensor, are codes from P0130 to P0167. There may be additional OEM P1-codes, that vary depending on the vehicle's brand, year and model. For example, it is very common, that on Honda's the wideband sensor codes include P1166 and P1167. Keep in mind, that the error can be found in both the sensor or the sensor wires.

Identification of wideband sensors

Wideband sensor codes also identifies the location of the sensor, such as sensor 1 or 2, cylinder row 1 or 2. Sensor 1 represents the primary/regulating wideband sensor at the exhaust manifold. Sensor 2 is the secondary/controlling sensor behind the catalytic converter. Sensor 2 are conventional O2 sensors, not wideband sensors. Cylinder row 1 is the bank, that contains cylinder number one in the engine's ignition order.